Description

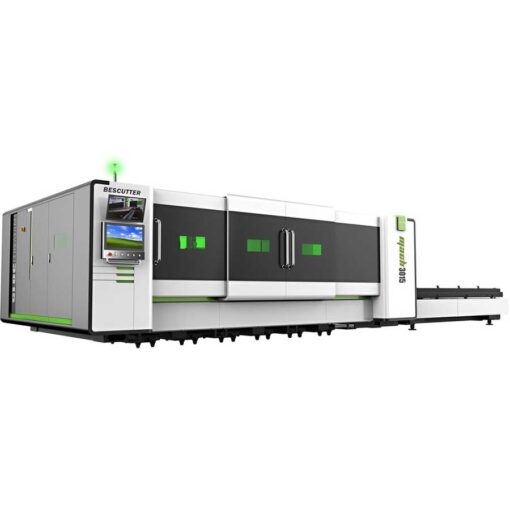

12,000 Watt 5′ x 10′ BesCutter MACH Speed Fiber Laser Cutter Han’s Photonics 12KW

12,000 Watt 5′ x 10′ BesCutter MACH Speed Fiber Laser Cutter Han’s Photonics 12KW

- Model Number: Mach Speed 3015

- Laser Table: 5 x 10

- Laser Generator: Han’s Photonics 12KW

- Laser Head: BOCI BLT smart head

- CNC Control System: CypCut FS 8000

- Water Chiller: S&A or TongFei 12000W

- High-Pressure Servo-control Valve: Hoerbiger (Germany)

- XYZ Direct Drive Servo Motors: Alpha(Germany) X (2×9,700W) Y(1×6,880W) Z (1×940W)

- High-Quality X, Y Rack, and pinion: Alpha (Italy)

- High Precision Gear & Reducer: Alpha(Germany)

- High Precision Linear Guide Rails: Rexroth (Germany)

- Energy Chain: IGUS (Germany)

- Pneumac Control: SMC or AIRTAC

- Throtte, Check & Solenoid Valves: FESTO (Germany),

- NORGREN(U.K),SMC(Japan)

- Electrical Element: Schneider Electric

- Industry Computer: NODKA

- Weight: 29,000 lbs.

- Positioning Accuracy:<=0.05 mm/m

- Repositioning Accuracy:0.02 mm

- X, Y Two-axis coordinated positioning speed (MAX) 240 m/min.

- Positioning acceleration (MAX) 2 .4 G

12,000 Watt 5′ x 10′ BesCutter MACH Speed Fiber Laser Cutter Han’s Photonics 12KW Specifications:

| Standard working area | 10′” x 5′ |

| Optional working area | 13′ x 6.5′ (4,000 x 2,000 mm) / 20′ x 6.5′ (6100 x 2000 mm) 26′ x 6.5′ (8000 x 2000mm) |

| X, Y, Z axis distance | 61″ (3050 mm)/120″ (1550 mm)/3.93″ (100 mm) |

| X, Y Two-axis coordinated positioning speed (MAX) | 240 m/min |

| Positioning acceleration (MAX) | 2.4 G |

| Positioning accuracy | ±0.05 mm/m |

| Re-positioning accuracy | ±0.02 mm |

| Laser resonator | BC Power/ Han’s/ MAX/ I PG/ Corative |

| Laser head | Ray Tools/ Precitec/ Han’s |

| Controlling System | FSCUT8000 (Shanghai)- Beckhoff (German Brand -Optional) |

| X-Y-Z Servo Motors | X-2x9700W; Y- 1x6880W ; Z-1x940W |

| Machine Weight | 28200 lbs (12800 kg) |

| Dimensions | 350″x 118″ x 87″ (8900 x 3000 x 2200 mm) |

-

Machine main body, direct drive system, Z-axis, laser cutting head,

shuttle table, laser source, control system, software and water chiller system,

transformer, stabilizer, etc. -

High-rigidity welded body, compact design and stable performance.

-

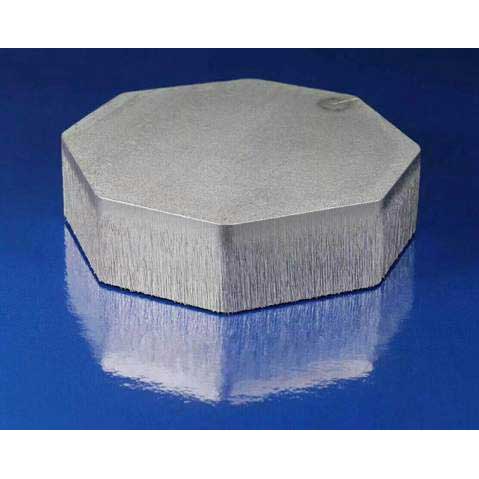

Special molding technique made aviation aluminum gantry: light weight, strong rigidity,

high precision, fast response and stable running. -

Integral molding die-cast aviation aluminum Z-axis is equipped with high precision ball

-

screw system, to achieving good rigidity, fast response and high precision.

-

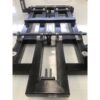

Synchronous drive system on both side of cutting gantry, equipped with high

torque direct driving system and perfect laser welded gear system. Ensure the

powerful driving, high accuracy cutting and excellent dynamic response. - FSCUT8000is EtherCATb us system designedf or ultra high power fiber

laser, featured by out of box service, easy to install and adjust. full solution

functions. It supports customization, automation and informatization

solutions, is the leading edge EtherCAT laser cutting control system on the

market. - Vision remnant reuse: capture remnant sheet by your phone camera or

machine camera to reuse the material with high etticiency.

Find edge: up to 500mm/s high speed with precision find sheet edge, also

provie optional find edge patterns to meet your production needs. - Programmable cutting gas control thanks to servo-control

valve, it can switch the type of cutting gas automatically,

and accurate control the gas pressure without user

intervention, user friendly and reduce gas consumption - With parallel auto exchanging shuttle table system ensures

synchronous running, good etticiency, and reliability.

CypNest:

Is an upgrade nesting software designed for CypCut/HypCut sheet laser cutting system. It integrates

advanced functions of drawing modification, quick nesting, toolpath generation such as heat concentration avoidance, analysis report, price report and more to meet your production needs.

Leapfrog:

Parabolic motion is adopted between lifting cutting contours, while the traditional cutting system uses “rectangular” motion. The system sets the take-off height and the highest height through PLC, and the contour switching process automatically realizes “frogjump”, which greatly improves cutting efficiency.

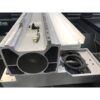

Linear Guide Rail

Linear slide rails use roller-type rolling elements instead of steel balls and are designed to achieve ultra-high rigidity and super-heavy load capacity. Through the realization of ultra-high rigidity, the processing accuracy can be greatly improved to meet the high-precision requirements; due to the

characteristics of the super-heavy load, the service life of the linear slide rail can be extended.

About Us

Worldwide Machine Tool is the leader in providing full sales, parts and service, financing, transportation and training of new and used machine tools for chip and fabrication clients across the United States, Canada and Mexico. Our warehouses and office is located just minutes north of Columbus, Ohio. With over 28 years of experience in the industrial machine tool industry, we have the knowledge and expertise to provide our customers with the best customer service, support and technical expertise on all new and used machine tools to meet their needs.

We buy and sell new and used ironworkers, shears, lathes, milling machines, drills, saws, press brakes, routers, turret punch models, presses, welders, deburring and beveling machines, plate rolls, laser, waterjets and associated tooling and accessories. We take pride in being a trustworthy partner that our customers rely on through the years. Our experienced sales team would love to help you with your next machine tool purchase. Give us a call today or Request A Quote. Call 614-255-9000 or Contact us today to experience the Worldwide Machine Tool difference.

Check us out on Twitter, Facebook, Youtube, and Instagram.

Worldwide Machine Tool LLC.

Terms and Conditions: https://www.worldwidemachinetool.com/terms-conditions/